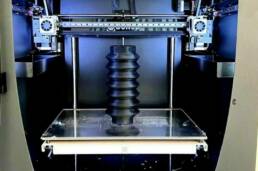

The revolution in production: large-format components and flexible shapes with our powerful 3D printer

There has been a real breakthrough in the world of production technology - 3D printing. This innovative technology enables us to produce components in previously unimagined dimensions. Our new 3D printer is specially designed for printing large-format components and sets new standards in terms of performance, reliability and precision. Using materials such as TPU and PLA, it opens up a world of possibilities. Let's take a look at the exciting features and benefits that this advanced 3D printer brings.

Steel processing

During steel processing in a Slovenian steelworks, the addition of a substance to the boiling steel produces a jet flame about 3 m high, together with a strong cloud of smoke. An extraction system with a downstream filter unit should be the remedy.

As if that were not enough, the solution used had to withstand 700°C for a short time, as well as a negative pressure of 3,000 Pa and a fan output of 70,000 m³/h.

Müngstener Brücke

During the restoration of Germany's highest railroad bridge, the "Müngstener Brücke" between Solingen and Remscheid, new bridge bearings were installed. The unusually high number of 126 bridge bearings for a bridge requires safe and durable protection to ensure the functionality of the bridge bearings for the next 35 years.

Telehandler

Machines and salt - that doesn't last long. In the French salt mine, machines do not have a long service life due to the heavy exposure to salt. After a very short time, all the metal parts are eaten away by the salt.

To prevent constant corrosion of the greased telescopic arms of the newly purchased Ausa telescopic handlers, their telescopes were completely encased in bellows.

Steel rolling mill

Heat, grease, dirt, extreme forces and sensitive components, the failure of which would result in disproportionately high costs. In the steel rolling mill, sheets weighing several tons are rolled down from 250 to, for example, 20 mm every minute. The final thickness of the sheets can be adjusted via the distance between the top and bottom rollers.

“Planet M” at the Expo 2000

The heart of the EXPO 2000 world exhibition was the EXPO Plaza and the Bertelsmann pavilion "Planet M/ Media for People".

Inside, a multimedia journey through time awaited the visitors. They entered the sphere, which resembled a spaceship, via an elevator platform. This elevator platform is considered to be the largest passenger elevator in the world. 200 people could be transported at the same time. The total weight of the elevator was almost 50 tons. Four pistons lifted it upwards using oil hydraulics, surrounded by a "giant bellow".

Innovation Award 2016

When professionally cleaning roads and paths, particularly in rural areas, a wide variety of different types of heavy soiling are encountered. In the newly developed sweeper attachment, the two housing parts are now suspended so that they float in relation to each other and the collection container at the front, into which the dirt is swept, can move up and down depending on the surface. To achieve a good result, the two housing parts must be sealed towards the front in the direction of travel.

Machine of the year 2018: The BIG X from Krone

The "KRONE BIG X" is the latest innovation from the agricultural machinery manufacturer Krone. The "BIG X" promises more comfort when chopping thanks to an innovative cab lift, which the driver can raise by 70 cm at the touch of a button. This gives the driver a perfect overview of the crop or of the forwarding wagon in parallel operation or when chopping. Another advantage is the greater distance to the chopping unit, which has a positive effect on the noise level in the cab.

Bellows to protect the cold chain

If a box truck and trailer are reversed up to a loading ramp, it can be completely loaded and unloaded without the driver having to uncouple the trailer. In refrigerated vehicles, the weak point is the transition between the trailer and the truck, as this is where the cold can escape through the open end walls, interrupting the cold chain. The cold chain is maintained by fitting a bellows. The bellows are concealed inside a rubber lip and are only extended pneumatically during the loading process. During the journey, the bellows are completely protected by the enclosure.

Slideway protectors for Tesla

The manufacturer of electric passenger cars TESLA has expanded its production capacities in the course of the new "3" model. New production sites have also been opened in Germany.

In order to meet the increased demand for electric vehicles, investments have been made in particular to ensure a smooth production chain. In this context, the company relies on our slideway protectors for machine protection to minimize downtimes.