Loading hoses are used in factory buildings and outdoors, in dry and damp weather, in summer and winter.

This means that their functionality must be guaranteed regardless of climatic and thermal loads. An important requirement when discharging, loading and conveying debris is a fast, smooth process without environmental pollution. In order for loading hoses to meet this practical requirement, they must fulfill a number of technological demands. In detail, these are

• Guarantee of a continuous discharge process

• Dust-free conveying and loading

• All-weather use

• Abrasion resistance, even with abrasive goods

• Prevention of static charging with flammable materials

• Heat resistance for hot conveyed goods

• Large stroke to be able to fill even small vehicles and containers

• Low overall height, guarantees maximum clearance height

Precise adaptation to the discharge material and the operating conditions ensure uncomplicated handling and a long service life.

Materials

Products are successful if they are maintenance-free and durable. The material is determined according to the type of goods to be loaded. As a rule, leather, textile fabric or plastic film are the starting materials. The material properties can be adapted to the intended use by coating with plastic or laminating with film. It is important that both the goods to be conveyed and the operational conditions are fully taken into account.

Dimensions

Our loading hoses are manufactured in sizes from approx. 200 mm nominal diameter, increasing by 50 mm in each unit, up to approx. 2000 mm diameter. Other dimensions are also available on request.

Single loading hose with filter venting

Single loading hoses are sufficient for low dust levels. They are a more cost-effective solution. The air dedusted by a filter escapes into the open air like a vacuum cleaner.

Double loading hose with venting

This design type is used when dust-saturated air obstructs the discharge process when filling closed containers and cannot escape.

Assembly

A connection plate is fitted to the silo or conveyor system, which has a connection piece for attaching the loading hose. Installation is straightforward. A filling cone can be attached to the lower end of the hose, which fits into the openings of the silo vehicles and containers.

Areas of application

Loading hoses are used to discharge, load or convey small, granular and powdery, hot and abrasive goods. The main users are cement factories, chemical plants, mills, malthouses, concentrated feed manufacturers, salt and coal mines, coal-fired power stations, companies in the food industry and many more.

Versions

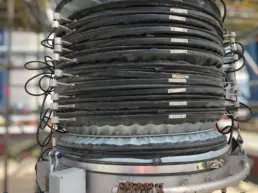

Rings made of spring steel wire are sewn in to guarantee exact folding. Additional stabilization is provided by folded spiral springs, which guide the hose back without any problems. A stroke ratio of minimum to maximum length expansion of up to 1:10 is possible.