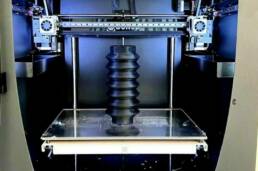

The revolution in production: large-format components and flexible shapes with our powerful 3D printer

The revolution in production: 3D printer

There has been a real breakthrough in the world of production technology - 3D printing. This innovative technology enables us to produce components in previously unimagined dimensions. Our new 3D printer is specially designed for printing large-format components and sets new standards in terms of performance, reliability and precision. Using materials such as TPU and PLA, it opens up a world of possibilities. Let's take a look at the exciting features and benefits that this advanced 3D printer brings.

Our 3D printer is not only capable of processing plastics such as PLA, but also high-quality TPU and even composite materials and metals. This variety of materials allows us to produce components for a wide range of applications. Whether it's flexible components or solid structures, this 3D printer masters every challenge.

Thanks to large-format printing, we can optimize our production processes. We no longer have to rely on the limitations of traditional manufacturing techniques, which often require expensive tools and molds. With our 3D printer, we can create components directly from digital models without incurring mold costs. This not only saves time and money, but also opens up completely new possibilities for the design and manufacture of products.

Another major advantage of our 3D printer is its ability to produce flexible components and shapes of all kinds. This enables us to offer customized solutions for our customers. Whether it is new products or the replacement of defective rubber bellows - we can produce individually according to our customers' needs. The short delivery time also guarantees that our customers can quickly benefit from our innovative solutions.

Our 3D printer is an example of the digital innovation that is revolutionizing our industry. The combination of advanced hardware and digital modeling opens up unimagined possibilities for us. Customers even have the option of sending us 3D models, which we can then turn into real products. This close collaboration between customers and manufacturers opens up a whole new era of product development and manufacturing.

Conclusion: The use of our powerful 3D printer for printing large-format components has taken our production capabilities to a whole new level. We can produce more flexible parts and molds than ever before, using a wide range of materials. The reduction in mold costs and short delivery times allow us to offer our customers tailor-made solutions and open up a new variety of products. The digital innovation spirit that drives this 3D printer opens up a world of creative possibilities for us. We are ready to take on the challenges of the future and offer our customers the best products and solutions.

Keep calm and be a BAD GIRL

Keep calm and be a BAD GIRL

Keep calm and be a pink BAD GIRL

Your advantages:

The protective glove complies with EN 388:2016+A1:2018.

Wet hands were yesterday

Wet hands were yesterday

The new TRUST is here!

Your benefits:

Thanks to the HIPORA® PU membrane, the Trust protective glove for technical assistance is windproof, waterproof and breathable. The additional reinforcement in the palm made of cow grain leather offers very high cut protection. The back of the hand is made of Spantex® and makes the protective glove comfortable to wear. For additional protection, there is a 3D silicone knuckle protector on the back of the hand.

The protective glove complies with EN 388:2016+A1:2018.

You can find an overview of the new features and further information here or in person, by e-mail or on the phone.

Developing the favorite

Developing the favorite

The ELK 3.0 SHORT BLACK:

Black elk leather, PTFE moisture barrier, RFID chip

Your advantages:

The special suppleness of the processed elk leather and the unique glove cut guarantee fatigue-free work with optimum tactility.

Whether fighting fires with extinguishing agents or during rescue operations - with this protective glove you are always on the safe side.

The PTFE membrane ensures that the firefighting glove is waterproof and breathable. In addition, and as a special feature, the new

has an integrated RFID chip in the pulse protection of the left and right glove.

Its excellent thermal insulation - even when wet - impresses and convinces the instructors in the fire container.

The firefighting glove complies with EN 659:2003 + A1:2008.

You can get an overview of the new features and further information here, in person, by e-mail and on the phone.

Product innovations in the field of hand protection

Product innovations in the field of hand protection

At the start of this year's RETTmobil trade fair in Fulda, we launched two product innovations in the field of protective gloves for technical assistance: the HYPA GRIP RESCUE and the NEW DIMENSION RESCUE.

The HYPA GRIP RESCUE is the counterpart to our HYPA GRIP firefighting glove. It impresses with its particularly high wet grip, as a CSM-coated KEVLAR has been processed in the palm. It is one of the few - if not the only - textile protective glove for technical assistance on the market that has a wet grip. A special construction of 3D fingertips and pre-curved fingers increases tactility (dexterity). Due to its construction of heat-resistant and cut-resistant textile materials, the HYPA GRIP RESCUE protects against both thermal and mechanical risks.

The NEW DIMENSION RESCUE also has a counterpart among the fire protection gloves - the NEW DIMENSION 3.0. Excellent tactility and high wearing comfort are the two most significant characteristics of the NEW DIMENSION RESCUE glove. It also offers very good protection against mechanical risks. Thanks to the use of particularly soft tanned cowhide/deerskin, it has an exceptional sense of touch and the best tactility - performance level 5 for dexterity.

Sustainably into the future

Sustainably into the future

We, Penkert GmbH, have been awarded ISO 14001:2015 certification and have thus taken the first steps towards a sustainable corporate future.

We are aware of our environmental obligations and actively strive to reduce our environmental impact. Internally, as well as externally, we have identified the risks associated with the environment and taken measures to mitigate them, while complying with legal and regulatory requirements. Throughout Penkert GmbH's value chain, we are committed to saving energy, protecting the environment, striving for carbon neutrality, complying with current environmental legislation and preventing pollution of the environment.

In addition to the ISO 9001:2015 certification, we are now proud to be certified according to ISO 14001:2015 and will continue to work on making Penkert GmbH more sustainable.

We focus on sustainability and innovation in order to do something good not only for our customers, but also for our environment.

Steel processing

Steel processing

During steel processing in a Slovenian steelworks, the addition of a substance to the boiling steel produces a jet flame about 3 m high, together with a strong cloud of smoke. An extraction system with a downstream filter unit should be the remedy.

As if that were not enough, the solution used had to withstand 700°C for a short time, as well as a negative pressure of 3,000 Pa and a fan output of 70,000 m³/h.

The solution we developed meets the requirements and represents a significant improvement in the working environment.

More information on this project is available on request.

Müngstener Brücke

Müngstener Brücke

During the restoration of Germany's highest railroad bridge, the "Müngstener Brücke" between Solingen and Remscheid, new bridge bearings were installed. The unusually high number of 126 bridge bearings for a bridge requires safe and durable protection to ensure the functionality of the bridge bearings for the next 35 years.

For the protection of the sensitive bearings, they rely on sleeves from our production. Precision and speed were also the decisive success factors in this project for professional installation and long-lasting use of the sleeves.

More information on this project is available on request.

Telehandler

Telehandler

Machines and salt - that doesn't last long. In the French salt mine, machines do not have a long service life due to the heavy exposure to salt. After a very short time, all the metal parts are eaten away by the salt.

To prevent constant corrosion of the greased telescopic arms of the newly purchased Ausa telescopic handlers, their telescopes were completely encased in bellows. All add-on parts are attached to the vehicle with both positive and non-positive locking, no drilling or welding is required. The bellows can be fitted and removed without leaving any traces. This aspect is particularly interesting for leasing or rental machines. The installation time is around one hour.

More information on this project is available on request.

Steel rolling mill

Steel rolling mill

Heat, grease, dirt, extreme forces and sensitive components, the failure of which would result in disproportionately high costs. In the steel rolling mill, sheets weighing several tons are rolled down from 250 to, for example, 20 mm every minute. The final thickness of the sheets can be adjusted via the distance between the top and bottom rollers.

Penkert bellows reliably protect the adjusting cylinders and spindles for many years. The last time we had to replace a bellows on a worm gear screw jack was after 35 years. The drawing and the manufacturing instructions for this bellows were kept in our document archive and could be examined and prepared accordingly even after this long period of time. It only took a few days to manufacture the new bellows.

More information on this project is available on request.